BS-4025 Motorized Metallurgical Inspection Microscope

Introduction

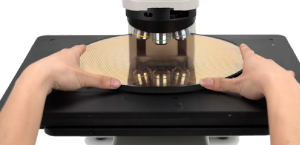

Whether it's small-sized sensors, large-sized wafers, or even the entire LCD display screen, they can all be observed with BS-4025 Motorized Metallurgical Inspection Microscope.

Details

Overview

Packaging & Delivery

Packaging Details:Strong Carton with Polyfoam Protection

Port:Beijing

Lead Time:Within 4-5 Weeks after Receiving Payment

Introduction

Introduction

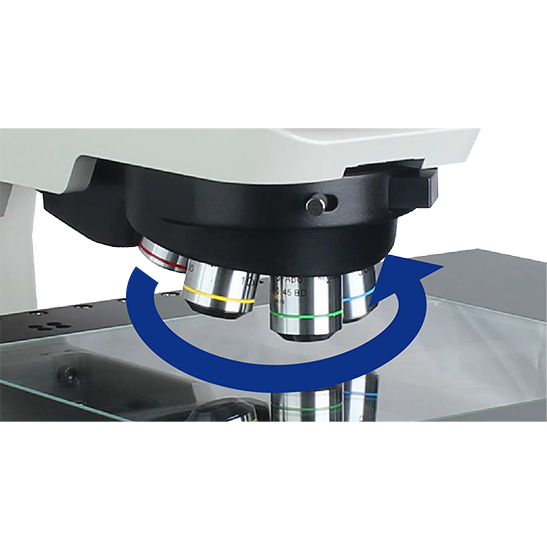

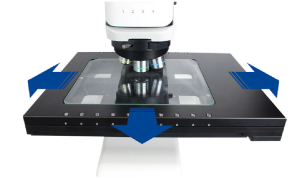

Whether it’s small-sized sensors, large-sized wafers, or even the entire LCD display screen, they can all be observed with BS-4025 Motorized Metallurgical Inspection Microscope. Fully motorized control and stable structure make daily work as comfortable and easy as possible. The ultra large range of movement allows for convenient and efficient movement and focusing of samples, as well as quick positioning of the sample range, making it an ideal tool for microscopic observation of large-area industrial samples.

Feature

1.LED illumination

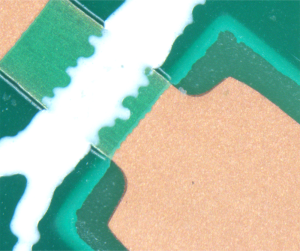

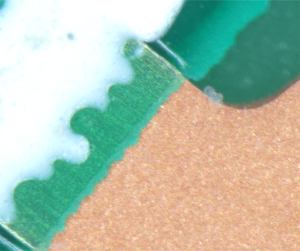

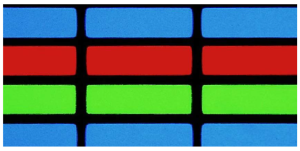

LED illumination can provide a constant color temperature and provide true color imaging at all brightness levels. And LED has a long service life, low power consumption, and easy maintenance in the later stage, making it an ideal microscope light source. Color changes in microscopic imaging under different light source and brightness level:

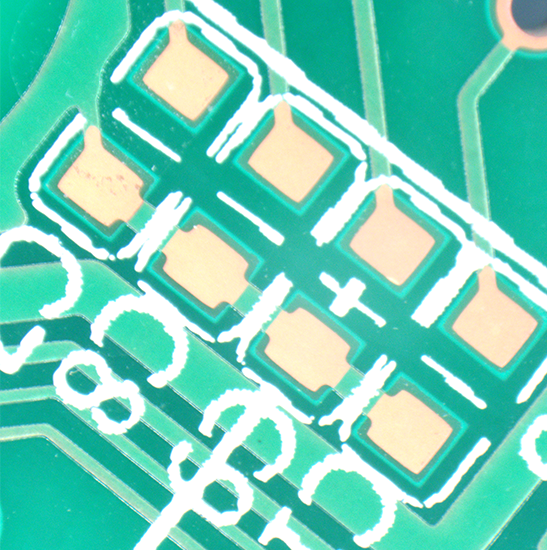

2.Wide applicable

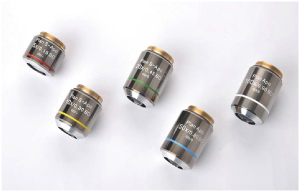

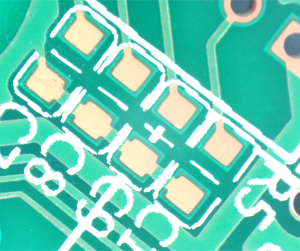

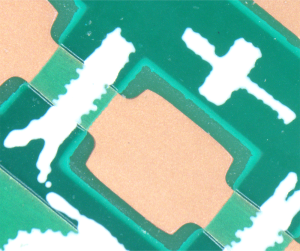

Optional specialized objectives with longer working distances are available to meet the imaging needs of industrial samples. The 5x overview objective can identify the macroscopic structure in the sample, and switching to 100x can observe alloy edges and material cracks. The conversion of different observation methods can provide a detailed understanding of your samples.

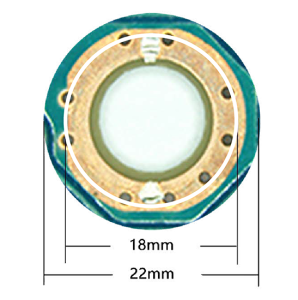

3.Wide field of view

BS-4025 microscope can achieve a wide field of view of 22mm under a 10X eyepiece, providing more comprehensive observation and faster sample observation. The eyepiece adopts a flat field distortion free design to prevent blurring of the field of view edge, the occurrence of mixed color aperture and other phenomena.

4.Software

Provide a comprehensive metallographic imaging analysis software with features such as image stitching, depth of field fusion, high-definition real-time HDR images and real-time/static measurement to meet the microscopic imaging needs of various industries.

5.Motorized control and open SDK for secondary development

The microscope is highly motorized, and functions such as focusing, stage movement, objectives conversion, observation mode selection, brightness adjustment, and aperture adjustment can all be motorized controlled by pressing the buttons at the front of the microscope body. If you want to build your own microscopy imaging operating system using BS-4025 as the imaging platform, we can also provide an open SDK for you to conduct secondary development and upgrades.

6.Sample protection structure

BS-4025 has a Z-axis height limit function to prevent collision between the sample and the objectives. The Z-axis reset function makes changing samples easier and safer.

7.Brightness memory function

It can remember the illumination brightness of using each objective and automatically adjust the light intensity to the corresponding brightness of each objective when different objectives are converted to each other, reducing visual fatigue and improving work efficiency.

4X

20X

50X

100X

8.Highly-Integrated control system

The control system commonly used for microscopic observation is located on the front of the microscope (close to the user), with a compact structure and a simple and clear interface. It is convenient for you to operate the microscope faster and easier when observing the sample. Reduce fatigue caused by prolonged observation and floating dust caused by large movements.

9.Erect image observation tube

Standard erect image observation tube, compared with traditional inverted image tube, the observation synchronization of stage movement and eyepiece is higher, making the operation under the objectives smoother.

10.Tilt angle adjustable trinocular viewing head

The tilt angle and eye point height can be adjusted to operate in a more comfortable posture, minimizing muscle tension and discomfort caused by prolonged work.

Application

BS-4025 can achieve various observation methods through modular combinations, such as bright field, dark field, polarizing, DIC, etc.

|

Observation method |

Bright field |

Dark field |

DIC |

Polarizing |

|

Reflection |

● |

● |

● |

● |

|

Transmission |

● |

– |

– |

– |

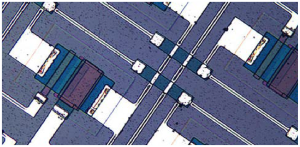

Reflection bright field

Adopting excellent NIS infinite optical system. Uniform field of view, bright and high color reproduction. Suitable for observing opaque samples such as semiconductors.

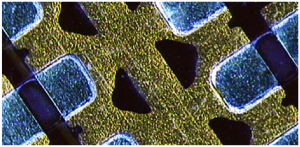

Dark field

It can achieve bright dark field observation and high-sensitivity detection of small scratches and other defects. Suitable for surface testing of high demand samples.

Transmission bright field

For transparent samples such as FPDs, optical components, etc., bright field observation can be achieved by transmitted condenser. It can also be used with accessories such as DIC and simple polarizing.

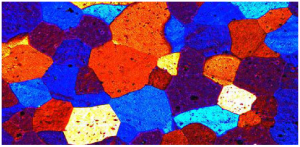

Polarizing

This observation method is suitable for specimens with birefringence, such as metallographic structures, minerals, LCDs, and semiconductor materials.

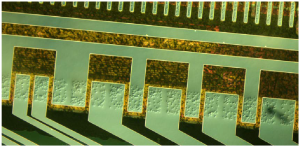

Reflection DIC

Used to observe small differences in precision molds. This observation technique can express subtle height differences that cannot be seen in ordinary observation through reliefs and 3D images.

Specification

|

Item |

Specification |

BS-4025 |

|

|

Optical System |

Infinity Color Correction Optical System |

● |

|

|

Viewing Head |

Trinocular head, 0-30° inclined adjustable, erect image, interpupillary distance: 47-78mm. Splitting ratio=0:100 or 100:0 |

● |

|

|

Eyepiece |

Wide field eyepiece EW10X/22mm, diopter adjustable, tube Φ30 |

● |

|

|

Objectives |

Infinite Semi-Apochromatic Metallurgical Objectives (BF & DF) |

5X/ NA=0.15, WD=20mm |

● |

|

10X/ NA=0.3, WD=11mm |

● |

||

|

20X/ NA=0.40, WD=12mm |

● |

||

|

50X/ NA=0.5, WD=10.6mm |

● |

||

|

100X/ NA=0.8, WD=3.5mm |

○ |

||

|

Nosepiece |

Motorized sextuple nosepiece |

● |

|

|

Stage |

Three-layer motorized stage, stage size 8”, moving range 200mm*200mm |

● |

|

|

Focusing System |

Coaxial coarse and fine focusing system, fine precision 0.8μm, travel range 35mm. Motorized control, with Z-axis reset and upper limit function. |

● |

|

|

Illumination |

Reflected illumination, 5W LED. Motorized metallographic illuminator for bright field, Kohler illumination. |

● |

|

|

Transmitted illumination, 5W LED, Kohler illumination. |

● |

||

|

Dark field module |

● |

||

|

Polarizer & Analyzer |

Polarizer and analyzer module |

● |

|

|

Condenser |

NA 0.65/0.1 condenser with aperture diaphragm |

● |

|

|

Filters |

Blue filter |

○ |

|

|

Green filter |

○ |

||

|

Yellow filter |

○ |

||

|

Ground glass |

○ |

||

|

C-mount Adapter |

0.5X C-mount adapter |

○ |

|

|

0.7X C-mount adapter |

○ |

||

|

1.0X C-mount adapter |

● |

||

|

Package |

Paper box with pearl cotton (single unit packaging) |

● |

|

Note: ● Standard Outfit, ○ Optional

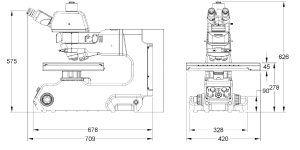

Dimension

Unit: mm